List of Equipment

VTL (vertical Turret Lathe)

Vertical turret lathes have the workpiece held vertically, which allows the headstock to sit on the floor and the faceplate to become a horizontal rotating table, analogous to a huge potter's wheel. This is useful for the handling of very large, heavy, short workpieces.

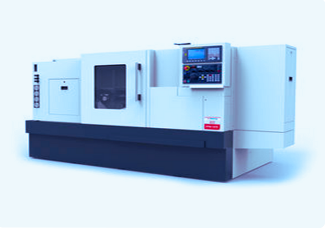

CNC (computer numerical control)

Computer Numerical Control – Taking digitized data, a computer and CAM program is used to control, automate, and monitor the movements of a machine. The machine can be a milling machine, lathe, router, welder, grinder, laser or waterjet cutter, sheet metal stamping machine, robot, or many other types of machines.

VMC (vertical machine central)

Vertical Machining Centers, also known as Vertical Milling Machines, create holes in flat parts. The VMC technology is favoured when four-axis work is done on a single face, such as in-mold and die works. Multiple adjustments are available on VMC.

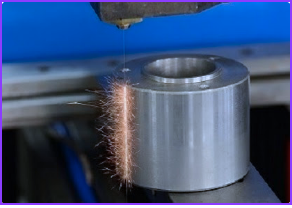

Wire Cut Machine

The wire-cutting machine works by sending a current between the wire and the workpiece, causing millions of sparks to fly. Therefore, this sparking generates heat, about 15,000 degrees Fahrenheit—enough to melt away microscopic bits of the workpiece, creating fine cuts and intricate shapes.

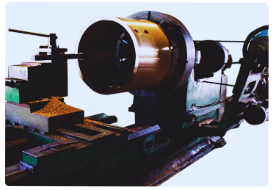

Heavy Lathe Machine

It is a stationary cutting tool used primarily for shaping metal, which is referred to as workpieces. The lathe machine removes unwanted parts of the workpiece to produce the desired product. The movements of a traditional lathe machine are manually controlled by an operator

Milling Machine

The milling machine is a type of production machine which removes the material from the workpiece by feeding the work post a rotating multipoint cutter. The metal removal rate is higher as the cutter has a high speed and many cutting edges.